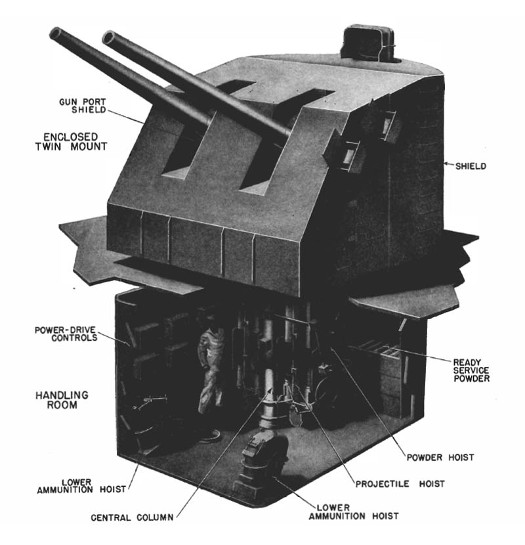

Above, a diagram of the USN’s 5 inch 38 calibre Mark 12 in the twin mounting. As usual with this blog, read on for relevance of image to text!

Above, a diagram of the USN’s 5 inch 38 calibre Mark 12 in the twin mounting. As usual with this blog, read on for relevance of image to text!

Notwithstanding all the brouhaha created by the “far left” protesters of “Black Lives Matter” [NB: Since the Liberal Democrats insist of labelling Moi as a member of the “far right”, I’ll reciprocate in kind] the UK as it is presently constituted is a democracy.

Being a democracy imposes limitations on governmental action, some of which can be very very costly. A particular area of great cost is of course the defence of the realm which can arguably be called a government’s first duty.

When it comes to the provision of hardware for the military we enter a minefield – pun intended!

You see there are three needs:

#1: the military need – they want the right hardware.

#2: the economic need – the said hardware must be affordable.

#3: the political need – the said hardware must be politically acceptable.

Now of course, despots like the monster who presides over the world’s largest open prison (some sections being closed) ~ North Korea ~ do not have to concern themselves with #3, but democratic leaders like the unfortunate present incumbent of #10 Downing Street have to.

Often as not, these needs conflict. Clearly the military want the biggest and the best and the fastest, heaviest armed piece of kit imaginable. The bean counters at HM Treasury are wanting the cheapest piece of kit imaginable. As we are currently discussing naval equipment a clear example of this is the sad case of 2-pdr [4 cm/39 (1.575″)] QF Mark VIII known to a generation (now for the most part dead) as the “pom-pom”. This gun was obsolescent by the time WW2 started but because the Admiralty had millions (literally) of ammunition in stock left over from earlier periods they insisted on it’s front line use right through to VJ Day! This when the UK had license manufacture of 56 calibre 40 mm OQF the so called “Bofors gun” which was the best automatic cannon AAA of WW2. Tragically, unlike the USN the RN was not allowed to put the Bofors gun onto it’s ships in anything like proper numbers, the bean counters (who of course were not aboard the ships) insisted on the “pom-pom’” continued use. Ships and men’s lives were lost because of this.

Buying the right kit however can cause a political problem. Had a politician in that era had pronounced that the British “pom-pom” was about as useless as a chocolate teapot and the Swedish Bofors gun was the bee’s knees, then MPs from both sides of the House would have been in uproar:

“British is best!”

“The minister is running down British military engineering which all members in this House will know is the best in the world!”

Now when it comes to medium calibre AAA of the period, the USN’s 5 inch DP (dual purpose) 38 calibre Mark 12 gun was the best medium calibre naval AAA in the world at that time.

At that time the RN had four calibres in use: 5.25 inch DP (battleships); 4.7 inch LA (destroyers) and AA (battleships); 4.5 inch DP (aircraft carriers and modified battleships) and 4 inch (cruisers, destroyers and frigates).

FACT: The USN’s 5 inch gun was superior to ALL these weapons.

Could a British minister have obtained the approval of the House of Commons to licence manufacture the American weapon and retire the British weapons?

I think readers know the answer!

This of course is all in the past. However this problem that we must invent and make all our own kit survives. It can be defined as “pig headedness”.

Pig headedness persists across all aspects of life and government policy. This applies across the world: No culture, ethnic group, faith group, gender or nationality is exempt!

This is of particular relevance to the question of electrical power generation.

When it comes to generating affordable electricity, BIG is nearly ALWAYS beautiful!

The “nearly” applies to places such as Loch Eriboll where there are few human inhabitants.

For the most part however, the UK is a densely populated country and low electricity prices are obtained by generating electricity by keeping costs down and efficiency levels up.

Politics however casts it’s own depressing pall over electrical power generation. We have the “barmy army” of Greens who insist that wind turbines and insulation are the answer. Some are honest enough to own up to cutting down on use as well!

Then we have the “barmy solution brigade” such as using wood chips in place of coal at the Drax power station.

And then of course we have “nuclear division” – who are the handmaidens of the military.

You see, the civil nuclear industry has always been an adjunct of the military. Military requirements and needs dictated it’s history. Not only in the UK but across the world.

QUESTION: Could civil nuclear power have been developed into a widespread and really cheap form of electricity?

ANSWER: Yes and no!

Technically the answer is yes. Politically the answer is no!

To demonstrate, I will now describe the efficient economic means of generating electricity by nuclear power. It will become obvious that it is politically impossible!

The nuclear reactor would be a heavy water reactor with heavy water as both moderator and coolant similar but different from Canada’s CANDU using slightly enriched uranium (0.85%).

The biggest difference will have such as Sir Ed Davy foaming at the mouth: that the aforementioned nuclear reactor provides the steam to a separately fired steam super-heater. The heat to be provided by coal!

Thus a power station rated at 1 GW or 1,000 Megawatts would have the nuclear reactor provide 87.5% of the heat energy with coal providing the remaining 12.5%.

Why is this not done?

Because pressurised water nuclear reactors were designed as power plants for nuclear submarines and the whole point was to provide the submarine with a power source that did not require air. Of course, the USN used PWRs in surface ships and they could have been made more efficient vessels had they incorporated oil fired steam super-heaters but the whole idea was to suggest the carrier could steam without refuelling. It needed to take on boards other stores ~ including fuel for it’s aircraft!

As for civil nuclear power? Well the while idea is to free our dependence on what the BBC have now started calling “dirty coal”!

NB: Of course, they MIGHT be persuaded to use wood chips!

The biggest problem however is the provision of heavy water:

Heavy water at high purity (>99%) demands huge amounts of electrical power for the repeated and large scale electrolysis. The simplest deuterium separation process was water distillation. At 13 kPa (51°C), the vapour pressure of the deuterated form of water is reduced by 5.51% compared to undeuterated water. Because it is only 1.015 at the normal boiling point of water, use of distillation under vacuum is very attractive. The advantage was the simplicity of this process. Water is boiled and condensed at opposite ends of a contacting tower, which is filled with a highly wettable packing, usually made of phosphor bronze. Throughout the contacting tower, liquid and vapour are brought into repeated contact. The falling liquid water becomes steadily enriched in deuterium while the rising vapour becomes steadily depleted. Though the separation factor is quite small, repeated contact amplifies the effect. It is common for such a system to have the equivalent of some hundreds of equilibrium contacts – i.e. increments of packing in which the exiting liquid and vapour are in equilibrium with each other. The process could hardly be simpler. Heat is applied at the bottom; cooling at the top. There are no moving parts and it is almost totally sealed. The only adjunct processes required are a small system to eject any air inleakage and good purification of the water feed to eliminate anything that could corrode or coat the packing. The limitation of water distillation lies in the quantities of water that must be evaporated. Because the separation factor is relatively small, the internal flows between the boiler and the condenser must be around 13 times larger than the feed flow. This is not a serious problem for small quantities of recovered water but it is huge detraction from the possible use of water distillation for primary production of D 2 O when factored onto the already large volumes associated with the low concentration of deuterium in natural water. For D 2 O production, around 100,000 times the product rate would have to be boiled and condensed. The temperature at which this heat of vaporization must be applied is admittedly fairly low but, even if heat were free, the volume of packing to handle immense vapour flows is prohibitively expensive.

Engineers developed a large scale heavy water plant using the Hydrogen Sulphide (HS) process, an industrial production method for filtering out of natural water the heavy water (deuterium oxide = D2O).

Today, D2O is used in particle research, in Deuterium NMR spectroscopy, deuteriated solvents for proton NMR spectroscopy, in nuclear reactors (as a coolant and moderator) in which case they are termed ‘heavy water reactors’ and in deuterated drugs. The method is an isotopic exchange process between H2S and H2O (“light” water), that produces heavy water over several steps. It is a highly energy intensive process. Seawater contains 180 parts per million of D2O.

The Hydrogen Sulphide (HS) process is still a costly way to produce Heavy Water.

Scientists and engineers have long recognised how much simpler it would be if one could use the water-hydrogen pair. Water and hydrogen do not, however, exchange hydrogen isotopes without a catalyst and a good catalyst is the key to applying this system. That requirement apart, this pair has many attractive features: it operates in a moderate temperature range; there are no toxicity or corrosion issues; and both substances are available as feedstocks on a large scale.

Water-hydrogen exchange was, in fact, applied to produce D2O. However, the catalyst undermined its economics. Water and hydrogen will exchange hydrogen isotopes in the presence of various metal catalysts. Platinum had long been recognized as the most effective metal for this purpose. However, because of the low solubility of H 2 in water, even a thin film of water reduces catalyst activity to near zero. To get round this impasse, the experimental plant used a succession of co-current contacts between hydrogen and superheated steam, each contacted separated by a condenser and a boiler/superheater. There was thus no natural counter-currency in the process and it was hugely energy-intensive. Scientists deemed the Hydrogen Sulphide process the more practical answer.

Development of a “wetproofed” catalyst was the key to a process based on water-hydrogen exchange. The idea was very simple: apply a film to the catalyst surface that is water-repellent but will permit ready passage of water vapour and hydrogen. In practice, developing really effective catalysts with high activity is a major undertaking.

If water-hydrogen exchange was developed into a monothermal water-hydrogen process and electrolytic hydrogen were being produced on a large scale (> 100 MW), the addition of a monothermal water-H 2 process to produce heavy water would produce D 2 O at an unbeatable price. This process is known as Combined Electrolysis and Catalytic Exchange (CECE).

THE SOLUTION:

What we need is International Co-operation through a UN agency.

There are countries who are blessed with plentiful hydroelectric resources. Were these counties to produce heavy water on a very large scale using CECE, the cost of heavy water would drop dramatically. IF CANDU reactors were produced on a production line basis, their costs would drop dramatically. IF depleted uranium was used commercially (and not just by the US Army as ammunition) the costs of uranium enrichment would drop dramatically. IF separately coal fired steam super-heaters were used to produce one eight of the output, the costs of the electricity would drop dramatically as the plants would become much more efficient.

Then there is what to do with the nuclear waste!

Here we should copy the USA – store it and do not reprocess it. The cheapest and best solution.

However: ALL this would require international co-operation!

ONE MORE THING: How to use depleted uranium:

DU already has civilian uses. DU is an excellent radiation shield ~ better than lead. If you’ve had an X-Ray you will have been in close proximity to some DU!

DU could be alloyed (in small quantities – 5%) to steel to make it more ductile and at the same time increase it’s tensile strength without increasing it’s susceptibility to corrosion too much.

HOWEVER: There would be one potentially internationally mandated and specified use that could account for a lot of DU: As THE alloy for bullion gold.

Gold bullion is 24 carats – pure.

Were the UN to mandate that bullion should be 23 carat alloyed with DU gold bullion would be 95.833% gold and 4.167% DU.

DU is a very hard metal but corrodes quickly. However, with gold having a melting point of 1,064°C and DU having a melting point of 1,132°C and with gold having a density of 19.3 g/cm3 and DU having a density of 19.1 g/cm3 DU is the perfect choice to harden gold.

Why should bullion gold become 23 parts gold 1 part DU?

It is often quipped about humankind that we as a species expend great effort to dig gold ore from the deepest parts of the Earth and then put great effort into refining it into it’s purest form: Only to put it back into the ground again! In the form of guarded vaults. Since DU is regarded as a hazardous metal and has military uses, what better solution can there be than to lock it up by making it the required hardener for bullion gold!

Oh dear! I forgot! The unfortunate Sir Ed Davy – who presumably fears that if he comes within 100 yards of any DU – even alloyed with gold – he will drop dead on the spot!

Herewith a very interesting website that supplies separately fired steam super-heaters: https://www.babcock-wanson.com/products/steam-boilers/fired-steam-superheaters/

For writing this article I will of course be deemed insane!

Speaking the Truth unto the Nation